Serving Americas countries

1931 Lawrence Road, P.O. Box 846

Kemah, TX 77565 - USA

Phone : +1 281 334 5015

Fax : +1 281 538 3622

FEATURES

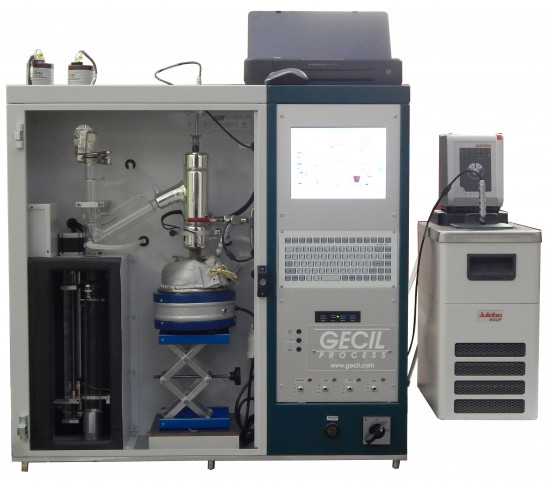

Fully automatic apparatus ASTM D1160, ISO 6616, JIS K 2254

Real time curves and synoptic display on Color LCD Display.

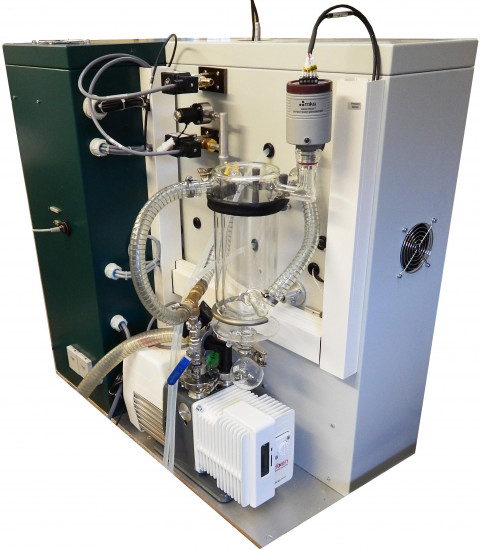

Automatic, variable speed vacuum lowering and regulation.

Automatic distillation rate control.

Automatic IBP, first drop and FBP detections.

Multiple fractions at atmospheric and vacuum pressure.

Automatic sample degassing and cleaning.

Run in °C, °F, mmHg or mBar.

Extensive library of distillation programs.

Data storage of unlimited distillation runs with USB key and/or LIMS transfer.

Built-in Ethernet interface.

Printer included.

DESCRIPTION

BENEFITS

Fully automatic ASTM D1160, ISO 6616, JIS K 2254

No operator intervention from start to FBP 650 C AET

vacuum dynamic lowering to achieve maximum recovery

Up to 10 analysis per day

Easy operation in local-mode with Linux GECDIST V7 software

No need of an external PC to operate all functions of GECDIST V7

Smallest footprint unit, with no external display or keypad

Ready for BIO-FUELS and BIO-OILS applications

More than 40 years experience manufacturing automatic D1160